Cell structures formed in new, cheaper mould

Researchers in the US have developed a cheap and rapid way to build cell structures in the lab, which can then be used for a large range of experiments.

Researchers in the US have developed a cheap and rapid way to build cell structures in the lab, which can then be used for a large range of experiments.

The new process has been dubbed ‘Block-Cell-Printing’, or ‘BloC-Printing’, and it has a number of advantages of previous techniques including inkjet cell printing technologies.

“We feel the current technologies are inadequate,” said Houston Methodist Research Institute nanomedicine expert Dr Lidong Qin.

“Inkjet-based cell printing leaves many of the cells damaged or dead. We wanted to see if we could invent a tool that helps researchers obtain arrays of cells that are alive and still have full activity.”

The Houston team’s approach produces two-dimensional cell arrays in about half an hour, prints the cells as close together as 5 micrometers (most animal cells are at least twice that distance apart), and allows the use of many different cell types.

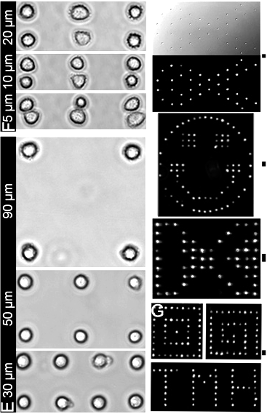

BloC-Printing manipulates microfluidic physics to guide living cells into hook-shaped traps in a silicone mould.

Cells flow down a column in the mould, past trapped cells to the next available slot, eventually creating a line of cells.

The position and spacing of the traps and the shape of the channel navigated by the cells is fully configurable during the mould’s creation. When the mould is lifted away, the living cells remain behind, adhering to the growth medium or other substrate, in prescribed formation.

Researcher tested the resulting structures for their utility in drug development and studies of tissue regeneration, cell function, and cell-cell communication.

By arranging metastatic cancer cells in a grid and examining their growth in comparison with a non-metastatic control, the researchers found they could easily characterize the metastatic potential of cancer cells.

The researchers also printed a grid of brain cells and watched as they formed synaptic and autaptic junctions.

“The cell junctions we created may be useful for future neuron signal transduction and axon regeneration studies,” Qin said.

“Such work could be helpful in understanding Alzheimer's disease and other neurodegenerative diseases.”

It is too early to predict the final market cost of BloC-Printing, but the materials of a single mould costs about $1 (US). When the mould has been fabricated, a researcher only needs a syringe, a suspension of living cells, a Petri dish, and a steady hand.

Inkjet cell printers can cost between $10,000 and $200,000.

While the fidelity of BloC-Printing is high, Qin modestly admits that inkjet printing remains faster, and BloC-Printing cannot yet print multi-layer structures as inkjetting can.

Print

Print